16 March 2012

At Yenakiieve Steel. Metinvest Group, new methods of efficiency improving has been introduced. Now operation of slag control system with Monokon manipulator being installed at BOF vessels No.1 and No.3 is under automated control. The same project is going to be implemented at BOF vessel No.2.

At Yenakiieve Steel. Metinvest Group, new methods of efficiency improving has been introduced. Now operation of slag control system with Monokon manipulator being installed at BOF vessels No.1 and No.3 is under automated control. The same project is going to be implemented at BOF vessel No.2.

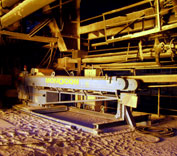

Monokon manipulator usage for slag control, when steel is tapping from the BOF vessel, is one of the technological features of steel makers operation from Yenakiievo. It is a formula for performance enhancing on account of ferroalloys and reducing agents losses reduction, steel ladles lining life increasing.

Furthermore Monokon units enable to improve quality, reduce time for steel treatment at Ladle-Furnace complex before its casting at CCM.

For the first time slag control practice, when steel is tapping from the BOF vessel, with Monocon manipulator usage was tested four years ago at BOF vessel No.1. Last year this system was put into operation at BOF vessel No.3. The next is BOF vessel no.2, which is already equipped with the appropriate unit, and soon manipulator will be used here as well.

Yenakiieve Steel experts decided not to rest on their laurels and improved manipulator control process. Today at BOF vessels No.1 and No.3 automated connection between Monocon controller and PSC “Melting” has been installed.

«Original design of Monocon unit is equipped with local mechanisms and process control system, -- told BOF Shop Manager Vasiliy Ivasenko. – However we required more extended and precise control of slag control process. That’s why experts at BOF PCS had to provide such control and they fulfilled this task perfectly. Now data from both manipulators are shown in the BOF vessels visualisation system and web-navigators used by Works’ management. All required information on slag control process is recorded in the data base in regular manner. The same system will be in operation at BOF vessel No.2».